Data Capture

Precision-Driven Data Capture for AI-Enhanced Digital Twins

At Envizion, we specialise in high-accuracy data capture techniques that form the backbone of our AI-driven digital twins. Our methodologies ensure precise spatial data collection, enabling real-time insights into facilities and operations. By employing adaptable techniques, we can swiftly respond to changes, scale operations, and update data to reflect newly installed plant equipment or future modifications.

Our AVA control coordinate system segments data into zones, objects, or areas, allowing for targeted data collection and efficient chronological updates as required.

Data Capture Methods

Envizion employs three key methods for data capture, each designed to meet specific needs and seamlessly integrate with our AI-enhanced digital twin platform for efficient analysis:

Laser Scanning

High-Precision 3D Scanning for Comprehensive Insights

Laser scanning lies at the heart of our data capture services, offering unparalleled accuracy and detail. Using advanced laser scanning technology, we provide:

- High-Resolution 3D Scans: Capturing intricate spatial data with sub-millimetre precision.

- 360-Degree Imagery: Ensuring complete visual coverage of environments.

- Seamless Integration: Direct compatibility with our digital twin and AI models for efficient analysis.

Our structured control grid guarantees the accuracy and reliability of each scan, empowering confident decision-making based on precise data.

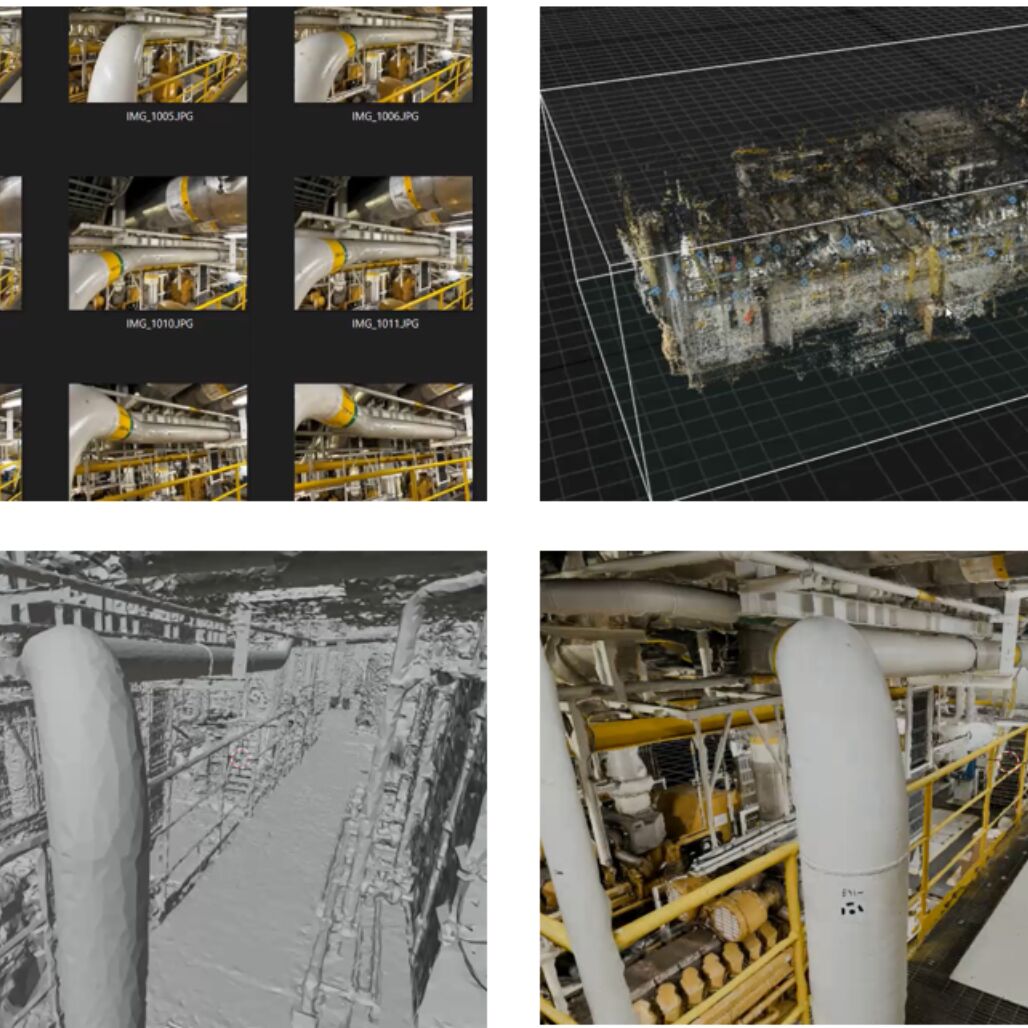

Photogrammetry

Supplementary Image-Based Data Collection

Photogrammetry serves as an alternative method for data acquisition, particularly useful in scenarios where laser scanning is impractical. This technique involves:

- High-Definition Imaging: Capturing hi-res photographs tied to ground control points.

- Point Cloud Generation: Processing images into point clouds representing surface geometry.

- 3D Mesh Creation: Point clouds are then converted into detailed 3D mesh models, ideal for digital twin integration.

While photogrammetry offers a cost-effective solution for certain applications, it is most effective when used alongside laser scanning and traditional dimensional control to enhance overall data accuracy.

Dimensional Control

Sub-Millimetre Accuracy with Total Station Measurements

For applications demanding the highest precision, our traditional dimensional control services employ total stations to achieve sub-millimetre accuracy. This method is ideal for:

- Critical Alignment Tasks: Ensuring exact placement and fit of components.

- Quality Assurance: Verifying dimensions against design specifications.

- Complex Installations: Facilitating accurate assembly in intricate environments.

By integrating total station measurements with our digital twin platform, we provide a robust solution for projects where precision is paramount.

Envizion

Why Choose Us?

At Envizion, technology meets expertise.

We don’t just offer cutting-edge digital twin solutions - we bring over 50 years of combined experience in Dimensional Control and advanced data capture. Our team’s deep industry knowledge keeps us ahead of evolving technologies, ensuring innovative, reliable, and high-quality service every time.

Let’s transform the way you manage and optimize your assets, together.